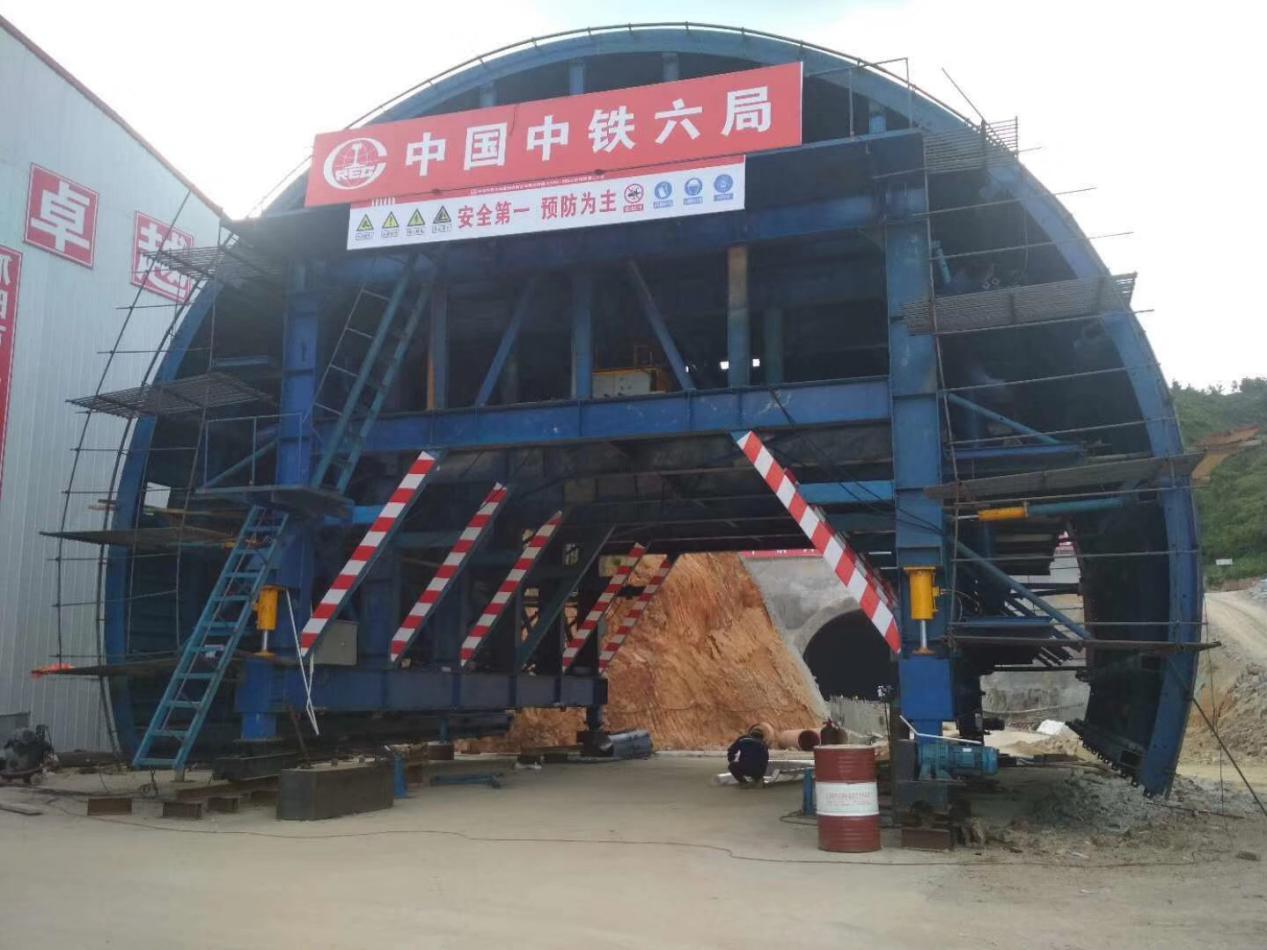

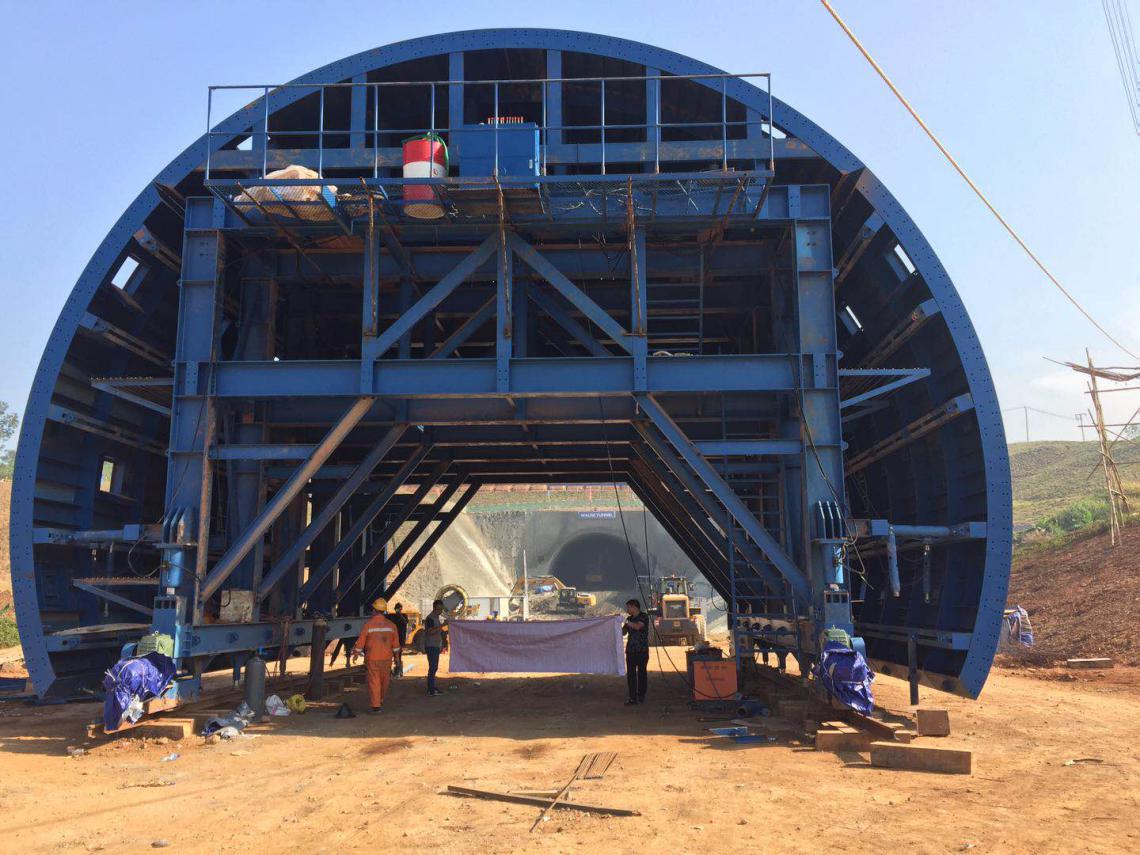

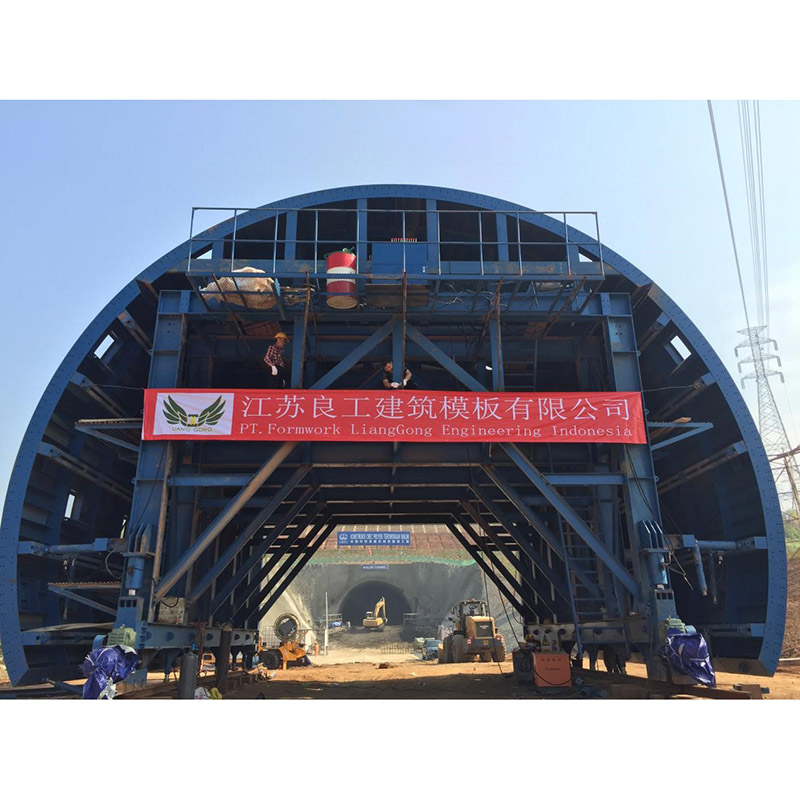

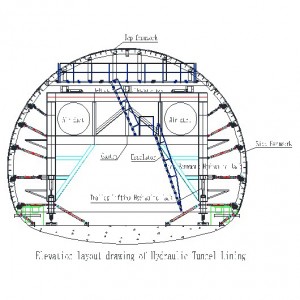

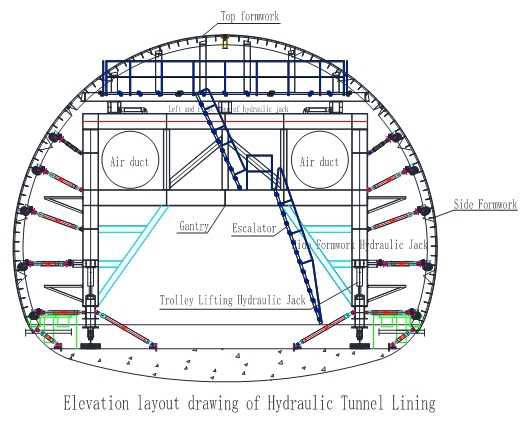

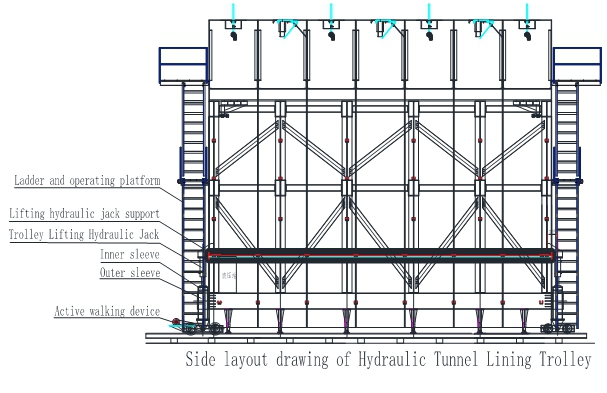

I-hydraulic tunnel lining trolley iyilwe yaza yaphuhliswa yinkampani yethu, yinkqubo efanelekileyo yokwenza i-formwork lining yeendlela zikaloliwe kunye nee-highway tunnels. Iqhutywa ziimoto zombane, iyakwazi ukuhamba nokuhamba yodwa, kunye ne-hydraulic cylinder kunye ne-screw jack ezisetyenziselwa ukubeka nokubuyisa i-formwork. I-trolley inezibonelelo ezininzi ekusebenzeni, njengexabiso eliphantsi, ulwakhiwo oluthembekileyo, ukusebenza okulula, isantya esikhawulezayo se-lining kunye nomphezulu we-tunnel olungileyo.

Itroli ngokubanzi yenzelwe uhlobo lwe-arch yentsimbi, isebenzisa itemplate yentsimbi edibeneyo eqhelekileyo, ngaphandle kokuhamba ngokuzenzekelayo, kusetyenziswa amandla angaphandle ukutsala, kwaye itemplate yokuhlukanisa yonke isebenza ngesandla, nto leyo edinga umsebenzi omninzi. Olu hlobo lwetroli ye-lining lusetyenziswa ngokubanzi ekwakheni i-tunnel emfutshane, ngakumbi ekwakheni i-tunnel concrete lining ene-plane kunye ne-space geometry eyinkimbinkimbi, ukuguqulwa kwenkqubo rhoqo, kunye neemfuno zenkqubo ezingqongqo. Iingenelo zayo zicacile ngakumbi. I-tunnel yesibini eqinisiweyo ye-concrete lining isebenzisa uyilo olulula lwe-arch frame, olusombulula ezi ngxaki kakuhle, kwaye kwangaxeshanye, iindleko zobunjineli ziphantsi. Uninzi lweetroli ezilula zisebenzisa ukuthululwa kwekhonkrithi yokwenziwa, kwaye i-linening troli elula izaliswe ziilori zepompo ezithwala ikhonkrithi, ngoko ke ukuqina kwetroli kufuneka kuqiniswe ngakumbi. Ezinye iitroli ze-lining ezilula nazo zisebenzisa i-integrated Steel Formwork, kodwa zisasebenzisa iintonga ezinemisonto kwaye azihambi ngokuzenzekelayo. Olu hlobo lwetroli ngokubanzi luzaliswa ziilori zepompo zokuhambisa ikhonkrithi. Iitroli ze-lining ezilula ngokubanzi zisebenzisa i-combined steel formwork. I-combined steel formwork ngokubanzi yenziwe ngeepleyiti ezincinci.

Ukuqina kwefom yentsimbi kufuneka kuqwalaselwe kwinkqubo yoyilo, ngoko ke isithuba phakathi kwee-arches zentsimbi akufuneki sibe sikhulu kakhulu. Ukuba ubude befom yentsimbi yi-1.5m, isithuba esiphakathi kwee-arches zentsimbi akufuneki sibe ngaphezu kwe-0.75m, kwaye i-longitudinal joint yefom yentsimbi kufuneka ibekwe phakathi kokutyhala kunye nokutyhala ukuze kube lula ukufakwa kweziqhoboshi zefom kunye nee-formwork hooks. Ukuba ipompo isetyenziselwa ukutyhala, isantya sokutyhala akufuneki sibe sikhawulezileyo, kungenjalo kuya kubangela ukuguguleka kwefom yentsimbi edibeneyo, ingakumbi xa ubukhulu be-lining bungaphezulu kwe-500mm, isantya sokutyhala kufuneka sincitshiswe. Lumka xa ugquma kwaye uthulula. Nika ingqalelo ekuthululeni ikhonkrithi ngamaxesha onke ukuze uthintele ukuthululwa kwekhonkrithi emva kokuzaliswa, kungenjalo kuya kubangela ukuqhuma kwesikhunta okanye ukuguguleka kwetroli.