Ifom yeKholamu yeMisebe yeTimber yeH20

Iinkcukacha zeMveliso

Iinkcukacha zoBugcisa

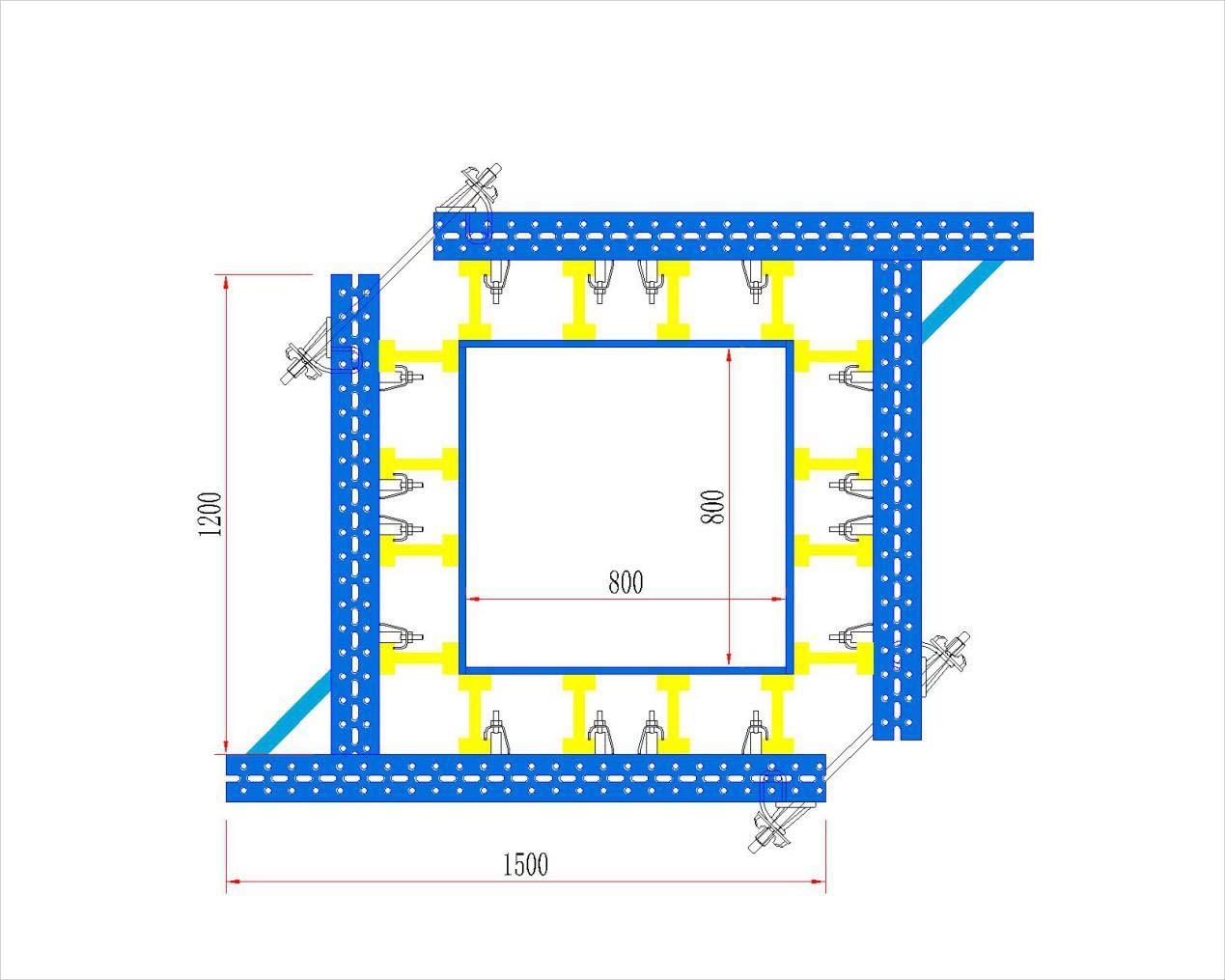

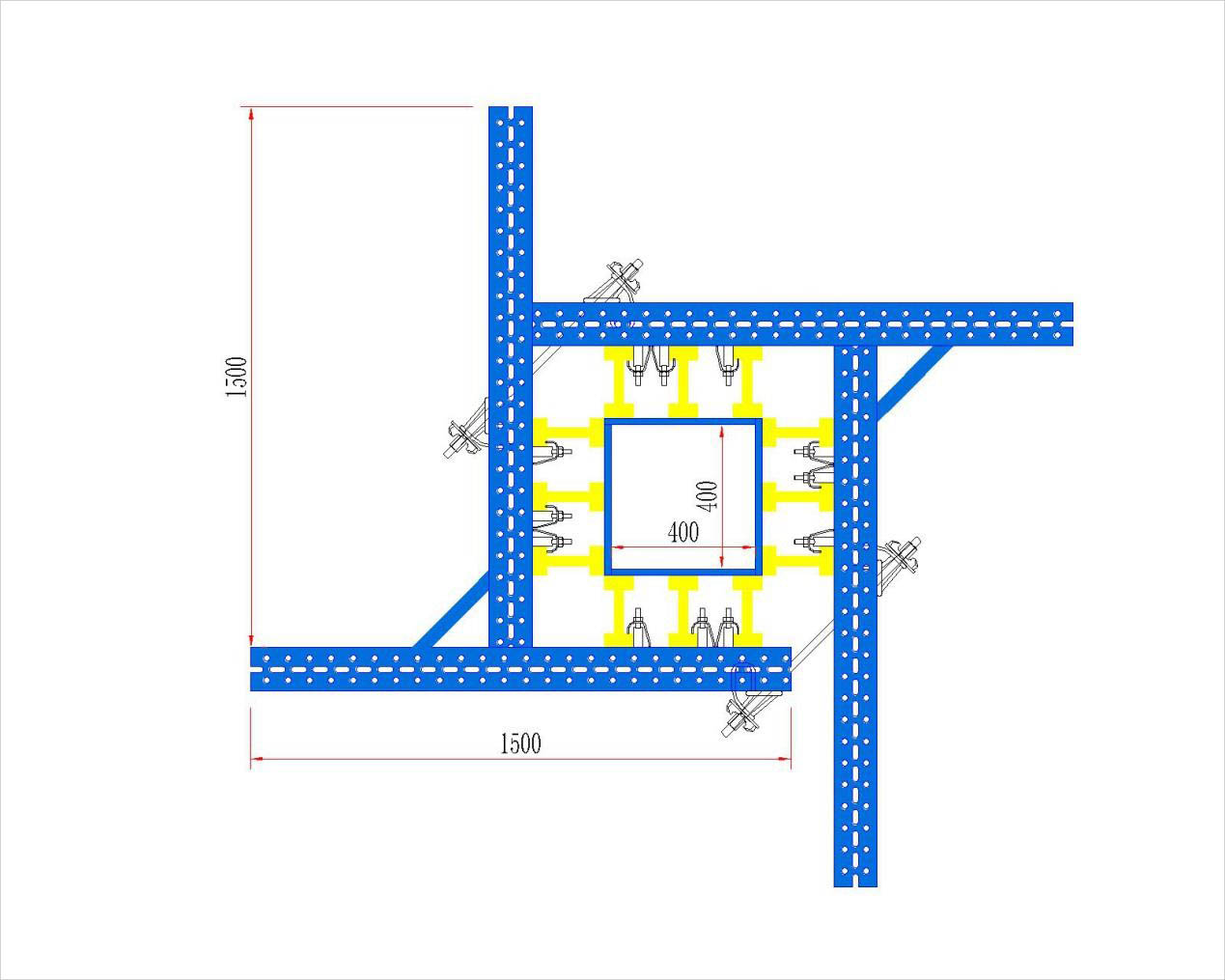

Umqadi wemithi ohlengahlengiswayo wekholamu

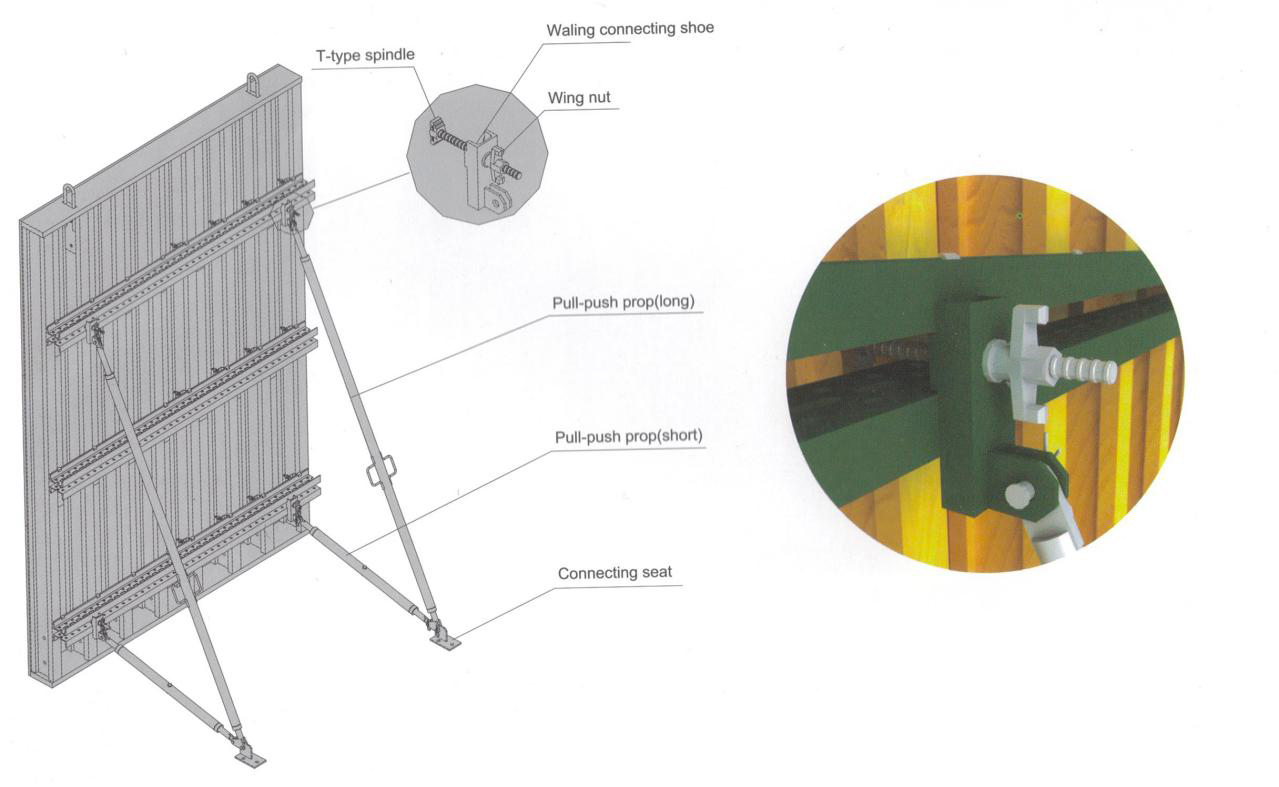

Isixhasi sodonga esijikelezayo

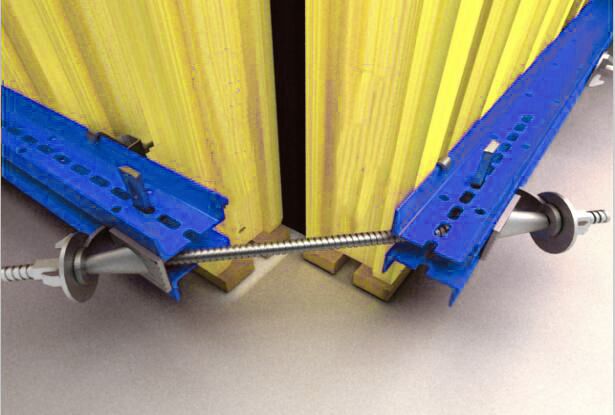

Ifom yekholamu yodonga yemiqadi yomthi kufuneka ixhotyiswe nge-spindle strut, esetyenziswa njengenkqubo yokulungisa njengoko kubonisiwe kumfanekiso:

Isicelo

Inkonzo Yethu

Ukubonelela ngenkxaso kuzo zonke izigaba zeprojekthi

1. Nika uncedo xa umthengi ethatha inxaxheba kwisimemo seprojekthi.

2. Nika isisombululo sethenda yefomula esilungiselelwe kakuhle kumxhasi oncedisayo ukuze aphumelele iprojekthi.

3. Ukuphuhlisa uyilo lwefomu, ukuphucula isicwangciso sokuqala, kunye nokuhlola umda wobudlelwane phakathi kokunikezelwa kunye nemfuno.

4. Qala ukuyila ifomwork ngokweenkcukacha ngokwebhidi ephumeleleyo.

5. Ukubonelela ngephakheji yesisombululo sefomula yezoqoqosho kunye nokubonelela ngenkonzo yokuxhasa eqhubekayo kwindawo.

Ukupakisha

1. Ngokubanzi, ubunzima obupheleleyo besikhongozeli esilayishiweyo buziitoni ezingama-22 ukuya kwezingama-26, ekufuneka ziqinisekiswe ngaphambi kokuba zilayishwe.

2. Iipakethe ezahlukeneyo zisetyenziselwa iimveliso ezahlukeneyo:

--- iibhanti: umqadi womthi, izixhobo zentsimbi, intonga yokubopha, njl.njl.

---ipalethi: iinxalenye ezincinci ziya kufakwa kwiingxowa emva koko kwiipalethi.

---iikheyisi zomthi: ziyafumaneka xa umthengi ecela.

---ubuninzi: ezinye iimpahla ezingahambelaniyo ziya kulayishwa ngobuninzi kwisikhongozeli.

Ukuhanjiswa

1. Imveliso: Kwisikhongozeli esipheleleyo, ngesiqhelo sidinga iintsuku ezingama-20-30 emva kokufumana intlawulo yokuqala yomthengi.

2. Uthutho: Kuxhomekeke kwizibuko lokutshaja apho uya khona.

3. Kufuneka uthethwano ngeemfuno ezikhethekileyo.